by Marjori Todd & Richard Best

by Marjori Todd & Richard Best

The Director, January 2011

Does your head spin with the alphabet soup of acronyms that are relevant to your professional life? Are you familiar with the requirements of the various agencies that have a level of jurisdiction over your funeral home practice?

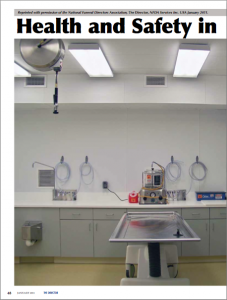

There are many aspects of funeral service where you are at risk of injury and infection. Hazards in funeral homes are wide ranging, and it is important, therefore, for funeral home employers to address those hazards to ensure that their employees have a safe and healthful work environment.

To provide you with a concise overview of the requirements, a summary of the main elements of the most important standards for funeral homes is provided in this article. This information is not meant to be a detailed discussion of every aspect or each point of the various standards discussed but rather a high-level overview that may be covered in a single reading.

OSHA

The Federal Occupational Safety and Health Administration is part of the United States Department of Labor, and its mission is to ensure safe and healthful working conditions by setting and enforcing standards and providing training, outreach, education and assistance. In addition to federal OSHA, there are also some states that have their own approved occupational safety and health programs. However, each state OSHA program must have regulations that are at least as strict as federal OSHA.

A number of activities in funeral homes fall under OSHA’s General Industry Standards. Of primary importance for worker safety is control of infection and working with hazardous chemicals, such as embalming fluids containing formaldehyde or formalin, as well as many other hazardous chemicals that may be present in the workplace.

Applicable OSHA regulations must be followed by funeral homes in order for them to remain in compliance. The Occupational Safety and Health Act of 1970 empowers OSHA with full authority to issue citations and penalties to covered employers with one or more employees if they are found to be in violation. Following are some of the details you should know for compliance with OSHA.

OSHA Hazard Communication Standard

The Hazard Communication Standard (29 CFR 1910.1200) was created to ensure that chemical hazards in the workplace are identified and evaluated, and that the information concerning those hazards is communicated to both employers and employees.

General requirements of OSHA’s Hazard Communication Standard:

• Provide a written Hazard Communication Program specific to your facility. The written program does not have to be long and technical, but it must be in writing.

• Provide a master list of all hazardous chemicals used at your facility.

• Ensure that containers of hazardous chemicals are properly labeled.

• Obtain a Material Safety Data Sheet (MSDS) for each hazardous chemical covered by the standard and used at the facility.

• Train all affected employees about the hazardous chemicals with which they work.

OSHA Bloodborne Pathogens Standard

The Bloodborne Pathogens Standard (29 CFR 1910.1030) applies to all workplaces in which employees may have contact with blood or other potentially infectious materials. The purpose of the BBP Standard is to reduce exposure and transmission of blood and body fluids to employees to prevent the contraction of diseases that can have severe consequences. One primary focus of the standard is the creation of a written BBP Exposure Control Plan.

General requirements of OSHA’s Bloodborne Pathogens Standard:

• Each funeral home that conducts embalming must develop a written BBP Exposure Control Plan designed to minimize or eliminate employees’ exposure to bloodborne pathogens.

• Hepatitis B vaccinations must be offered to all employees who are potentially exposed, unless the employee has previously received the complete hepatitis B vaccination series, antibody testing has revealed that the employee is immune or the vaccine is contraindicated for medical reasons.

• The employer must document annually the consideration and implementation of appropriate commercially available and effective safer medical devices designed to eliminate or minimize occupational exposure. Obtaining input from affected non-managerial staff members is also required documentation.

• Documented annual review and update of the Exposure Control Plan is required.

• A post-exposure evaluation and follow-up procedure must be in place in the event of an employee’s exposure to blood or OPIM (Other Potentially Infectious Material), such as a puncture wound from a suturing needle.

• Employees must use at least Universal Precautions, as defined by OSHA, with all procedures that entail the possibility of exposure to blood or OPIM. Universal Precautions assumes that all human blood and certain body fluids are treated as if known to be infectious.

• Drinking and eating are not allowed in the embalming room and other work areas where there is a reasonable likelihood of exposure to blood or OPIM.

• The facility must have a written housekeeping schedule for those areas that may be contaminated with blood or OPIM.

• Only disinfectants or sterilants that are EPA registered or FDA cleared may be used to decontaminate surfaces or instruments that have been contaminated with blood or OPIM.

• Tongs, forceps or other appropriate engineering controls must be used to reach into cleaning containers to pick up reusable sharps.

• Scrub sponges and other potentially contaminated instrument cleaning tools must be properly disinfected and stored.

• A biohazard warning label must be attached to containers of potentially infectious material.

• Waste cans used for containment of biohazards must be lined with biohazard bags. The regulated waste must be placed in a container that is closable.

• Sharps containers must be easily accessible to personnel and located as close as feasible to the immediate area where sharps are used.

• Employees with occupational exposure to bloodborne pathogens must be trained on the safety procedures related to blood or OPIM.

• A sharps injury log is used to record injuries resulting from sharps.

OSHA Personal Protective Equipment Standard

The Personal Protective Equipment (PPE) Standard (29 CFR 1910 132, Sub- part I) requires that personal protective equipment be utilized for many tasks performed in funeral service settings, such as preparation rooms. Coveralls, shoe covers, gloves, chemical goggles, face shields, head covers, surgical masks and respirators all have application in funeral service settings. Coveralls, aprons or gowns need to have full sleeve coverage and be impervious to blood, formaldehyde and other chemical agents.

General requirements of OSHA’s Personal Protective Equipment Standard:

• The employer must perform a job hazard assessment for the tasks conducted at the funeral home to determine what PPE is needed. A written certification of this assessment is required.

• Employees required to wear personal protective equipment must be trained in the proper use of that equipment. Again, a written certification that workers have received and understood this training is required.

• Gloves and eye protection designed for protection against the hazards found in the embalming room are required.

OSHA Respiratory Protection Standard

Whenever respirators are required in the workplace, the requirements of the Respiratory Protection Standard (29 CFR 1910.134) are triggered. There are two basic classes of respiratory hazards encountered in funeral home settings. Hazards may be in the form of particulates, such as flu viruses, droplets containing tuberculosis bacteria, etc., or they may be in the form of organic vapors, such as formaldehyde. Generally speaking, a respirator that is suitable for most biological particulates (respirators such as N95s or Powered Air Purifying Respirators) provides no effective protection for organic vapors and vice versa. There are very expensive respirators on the market that are capable of providing protection against both of these types of hazards, but such respirators are not generally encountered in funeral homes.

General requirements of the Respiratory Protection Standard

• A written Respiratory Protection Program and a qualified administrator are required.

• All employees required to wear a respirator must be medically evaluated to ensure that the respirator does not place an undue physiological burden on an employee’s health.

• If the use of respirators is required because the permissible exposure limit for formaldehyde has been exceeded, then it is a requirement of the Formaldehyde Standard that the affected worker must receive not just a medical evaluation but rather a medical examination annually.

• The Formaldehyde Standard also requires that the cartridge for a respirator used for protection from formaldehyde must be changed after at least every three hours of use.

• Employees must be fit-tested with the same make, model, style and size of respirator that will be used. Fit testing must be repeated at least annually, and records must be kept.

• Training in respirator use must be provided annually, and records of the training must be kept.

• For situations where a respirator is not required but an employee chooses to wear one on a voluntary basis, the employee must still be provided with the information included in Appendix D of the standard, and the employer must ensure that the employee is medically evaluated and cleared to use the respirator.

OSHA Formaldehyde Standard

Formaldehyde/formalin is a common hazardous chemical used for embalming. This chemical is specifically regulated by OSHA and has its own OSHA standard (29 CFR 1910.1048) that sets maximum exposure levels and monitoring requirements, and requires engineering controls designed to protect workers from the negative effects of formaldehyde exposure.

General requirements of OSHA’s Formaldehyde Standard:

• Measurements of the level of exposure to formaldehyde during embalming must be taken. Two measurements are required: a Time-weighted Average (TWA) and a Short-term Exposure Limit (STEL). TWA and STEL measurements are done by wearing a dosimeter badge and are different from measurements taken with a detector tube. Detector tubes provide measurements on the spot, but they are not the same thing as Time-weighted Average or Short-term Exposure Limit measurements required by the standard. TWA and STEL measurements are made over a period of time and are not spot measurements. They require mailing the personal dosimeter to a laboratory for analysis.

• Affected employees must be notified of the monitoring results.

• Engineering controls, such as an effective ventilation system, must be utilized, along with work practice controls to minimize exposure to formaldehyde so that exposure is below the Action Level of the standard.

• Annual formaldehyde safety training must be provided.

• Protective clothing and personal protective equipment must be provided.

• A change room must be provided.

• A medical surveillance program is required if exposure at the Action Level or Short-term Exposure Limit occurs or whenever employees show signs or symptoms of overexposure to formaldehyde no matter the level of measurement.

• An emergency eyewash and drench shower in the embalming room must be provided.

• Although not specifically mandated, work facilities using other chemicals, such as glutaraldehyde, will also benefit from exposure monitoring to determine level of exposure.

Medical Services and First Aid Regulation

This is one of the shortest of all OSHA standards; the federal version (29 CFR 1910.151) has just four sentences. The hitch, however, is that there is a lot of information covered in those four sentences. The first topic covered is medical services or first aid.

The standard requires that if there is not an infirmary, clinic or hospital in near proximity, then an employee is required to be adequately trained to render first aid. In addition, adequate first aid supplies must be readily available.

Just what does OSHA mean by “near proximity”? A rule of thumb is that if an injured worker requiring first aid cannot receive it within three minutes, a person is required to be trained to provide such first aid in the workplace.

You can make sure that a person is adequately trained to render first aid in your facility by having him or her take a short course provided by such organizations as the Red Cross, local community colleges, etc. To download an excellent fact sheet of what “adequate first aid supplies” should be available in your workplace, visit Minnesota OSHA at www.dli. mn.gov/osha/pdf/fact_firstaid.pdf.

The part of the federal standard that deals with eyewashes and drench showers is even shorter, just a single sentence. To properly explain all of the things that should be incorporated into an eyewash and drench shower would require a separate article. The best management practice, therefore, is to make sure that your eyewash and drench shower comply with the current ANSI standard Z358.1. Al- though this ANSI standard has not been formally incorporated by reference into the federal OSHA Standard, some state OSHA plans have formally incorporated various editions of the ANSI standard over the years. But whether your workplace is in a state that has formally adopted the ANSI standard or not, the best management practice is to comply with ANSI requirements. Doing so will ensure that you go beyond OSHA’s minimal requirements. For more detailed information on this topic, download “Safety Equipment in the Preparation Room” located under “Industry Publications” in the “News” section at www.dstlimited. com.

Fire Extinguisher Training Standard

It’s perhaps surprising to learn that OSHA itself does not strictly require portable fire extinguishers in most general-duty workplaces. But this fact is a somewhat moot point since almost all workplaces already have portable fire extinguishers present whether they are strictly required by OSHA or not.

If portable fire extinguishers are present in a workplace, then such presence triggers several OSHA requirements (29 CFR 1910.157). If portable fire extinguishers are present, they must:

• Be properly mounted.

• Be properly identified.

• Have a current annual inspection tag in place.

• Be of the appropriate rating type, usually Type ABC for most funeral service settings.

• Have an MSDS (Material Safety Data Sheet) available if the fire extinguisher itself is pressurized or contains any hazardous chemicals.

Fire extinguishers must be inspected monthly by the employer, and it is a best practice to record those monthly inspections. The biggest requirement for portable fire extinguisher use, however, is that annual training must be provided by the employer for all employees who are expected to use portable fire extinguishers.

Walking and Working Surfaces

Thousands of workers are injured each year in slips, trips and falls. The basic rules of the Walking and Working Surfaces Standard (29 CFR 1910.21 Subpart D) apply to things that most people know intuitively. Problems usually arise, however, when we get too busy and forget the basics.

General requirements of the Walking and Working Surfaces Standard include:

• Ensuring that walkways are well lit, have non-slip surfaces and are free from obstructions.

• Cleaning up spills immediately and displaying warning signs, when appropriate.

• Ensuring that staff members avoid steps, stairs and uneven surfaces when carrying or moving loads.

• Making sure that any floor openings and holes are properly covered or repaired.

Manual Handling and Ergonomics

At the time of this writing, federal OSHA does not have an ergonomics standard per se. That does not mean, however, that your workplace will not be cited for violations in this regard. For situations where there is no specific standard, OSHA can use what is known as the “General Duty Clause” as its authority. OSHA and NIOSH (National Institute for Occupational Safety and Health) both make lots of resources pertaining to ergonomics and safe lifting available on their websites: www.osha.gov and www. cdc.gov/niosh.

The basic points for training and careful supervision are:

• Assess manual handling activities carried out by your employees and, where possible, avoid or minimize manual handling.

• Train staff in safe-lifting techniques and practices for the deceased and on moving empty or occupied coffins.

• Provide mechanical aids, such as mortuary lifts, roll-in cots, trolleys, church trucks, vehicle lifts, etc.

Conclusion

The problem with any article on occupational safety and health is that there is never a true ending point. This article could continue by addressing many other issues, including regulated medical waste, backflow prevention, vehicle safety, etc. But those are topics best left for another time. Remember, OSHA’s goal is to prevent injuries and illnesses in the workplace, and its regulations represent only the minimum that must be done.

NFDA members with further questions can access the NFDA OSHA Hot- line at 800-633-2674 or search the NFDA website (www.nfda.org). Readers can also access Duncan Stuart Todd resources by calling 877-832-6898 (fax: 775-832-6895) or emailing info@dstlimited.com. The website (www.dstlimited.com) posts links to many codes and regulations. Click on “News” in the top navigation bar and on “Industry Resources” in the side bar.

Richard Best is corporate director of OSHA compliance for Stericycle Inc., a leader in the field of regulatory compliance providing OSHA training in healthcare and funeral service facilities. He can be contacted at the NFDA OSHA Hotline, 800 633 2674, or by email at rbest@stericycle.com.

Marjori Todd is president of Duncan Stuart Todd Ltd., The Preparation Room Specialists, and may be reached at 720-583-1886 or info@duncanstuarttodd.com, or visit duncanstuarttodd.com.